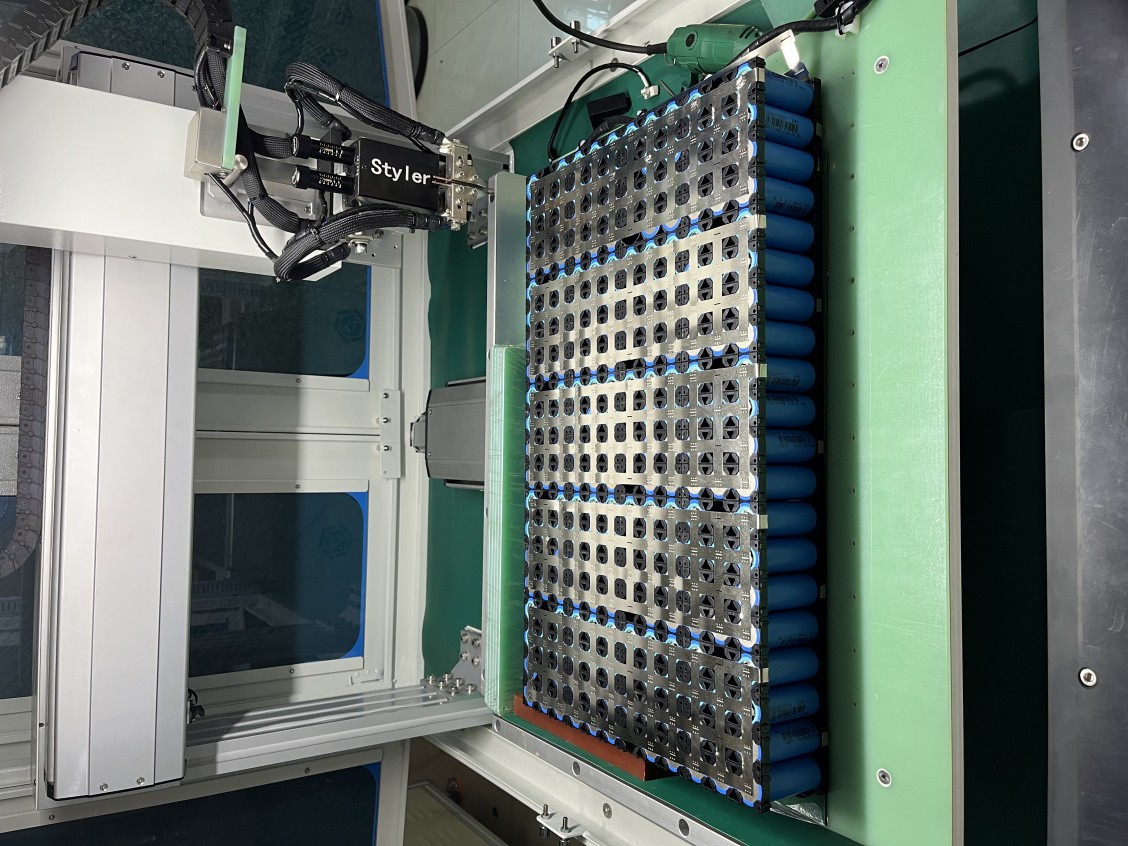

A cikin saurin haɓaka duniyar kera batir-ikon sarrafa komai daga EVs zuwa kayan lantarki na mabukaci da ma'ajiyar grid-walda yana tsaye azaman mahimmanci, amma sau da yawa ƙalubale, tsari don haɗa fakitin baturi. Mutuncin kowane haɗin kai yana tasiri kai tsaye amincin fakitin, aiki, da tsawon rayuwa. A STYLER, mun ƙware a cikin ci-gaba waldi da mafita na taro don haɗin kai-matakin, gami da juriya na daidaici.Spot Welders, Injin walda na Laser mai sauri, da Module Baturi mai juyawa & Layin Taro.

We'Na tattara tambayoyi goma mafi yawan lokuta da ƙungiyar injiniyoyinmu ke ci karo da su game da walƙiya fakitin baturi, suna ba da ƙwararrun ƙwararru don taimaka muku kewaya sarƙaƙƙen sa.

1. Menene mafi dacewa tsarin walda don haɗa nau'ikan sinadarai na silinda ko busbar fakitin baturi?

Don haɗa ƙwayoyin halitta cikin na'urori ko haɗa sandunan bus a cikin fakiti, Welding na Resistance Spot galibi zaɓi ne da aka fi so.'sa sauri, tsada-tasiri, kuma abin dogara hanya don ƙirƙirar mahara karfi lantarki haši. Farashin STYLER tabo walda, Yin amfani da fasahar transistor na ci gaba, isar da ingantacciyar gudu da kwanciyar hankali, tare da ci gaba da amsawa na yau da kullun da sarrafawa mai daidaitawa don sarrafa bakin ciki, abubuwa masu mahimmanci kamar bus ɗin nickel-plated.

2. Ta yaya za mu hana zafi fiye da kima da lalata ƙwayoyin batir a lokacin fakitin walda?

Gudanar da thermal yayin taron fakiti yana da mahimmanci. Makullin shine sarrafa shigarwar makamashi tare da matsananciyar daidaito a wuraren haɗin gwiwa. Madogaran Resistance Spot Welders na tushen mu na Transistor suna cimma wannan ta hanyar gajeren gajere, madaidaiciyar zagayowar walda (millise seconds), rage yaduwar zafi. Don waldawar Laser, zabar madaidaitan sigogi da amfani da na'urorin sikanin galvanometer masu sauri suna gano shigar da zafi. Tsarin mu na iya haɗa sa ido na zafi don tabbatar da cewa sel na kusa sun kasance cikin iyakoki mai aminci.

3. Aluminum da jan karfe-aluminum composites sun zama gama gari a cikin fakitin busbars. Menene mafita na walda?

Welding waɗannan kayan yana buƙatar zaɓin tsari a hankali. Don waldawar tabo, babban aikin nickel mai tsafta yana buƙatar babban halin yanzu a cikin ɗan gajeren lokaci. STYLER's transistor welders suna isar da buƙatun gaggawa mai ƙarfi, ƙarfin bugun jini. Don waldawar Laser na busbars na aluminum da haɗin kai, yana da tasiri sosai. Koyaya, don sandunan bas ɗin jan ƙarfe kawai a cikin taron fakitin, waldawar laser tana ba da ƙalubale saboda haɓakar haske da haɓakar zafi. Wata madaidaicin aiki kuma shawarar da aka ba da shawarar ita ce a yi amfani da basbars na jan karfe-aluminum hadewar busbars (kayan da aka rufe), inda ake yin walda na Laser akan Layer na aluminum, yana tabbatar da abin dogaro da kwanciyar hankali.

4. Yaya mahimmancin tsaftar kayan abu da shiri na fakitin walda?

Matukar mahimmanci. Oxides, mai, da gurɓataccen abu akan sandunan bas ko tasha suna haifar da rashin daidaiton ingancin walda, ƙara ƙarfin lantarki, da yuwuwar gazawar. Tsarin taro mai ƙarfi ya kamata ya haɗa da tsaftacewa mai kyau (misali, tsaftacewar Laser, tsaftacewar plasma) nan da nan kafin walda. Layin Taro na Fakitin Baturi na STYLER na iya haɗa tashoshi masu sarrafa kansa don tabbatar da daidaiton yanayin saman kowane haɗi.

5. Ta yaya za mu tabbatar da m weld ingancin a high-girma fakitin samar?

Daidaituwa ya fito daga kwanciyar hankali na kayan aiki, sa ido kan tsari, da sarrafa kansa. Injin mu suna da:

Sa ido kan Tsari na ainihi: Auna juriya mai ƙarfi (walkin tabo) ga kowane walda.

Ikon daidaitawa-Madauki: Daidaita sigogi ta atomatik dangane da martani.

100% Binciken Bayan-Weld: Haɗa tsarin hangen nesa don sanya weld da gwajin juriya na lantarki a cikin layin taro don tabbatar da inganci.

6. Menene mahimman fa'idodin walƙiya na laser a cikin taron fakitin baturi?

Welding Laser yana ba da sassauci na musamman a cikin nau'ikan nau'ikan walda (layuka, da'irori, kwane-kwane), ƙarancin injin injin, da ikon waldawa a cikin keɓaɓɓun wurare a cikin tsarin fakitin. Yana da manufa don walda ƙarshen faranti, suturar sutura (inda ya dace), da kuma hadaddun sifofin motar bas. Yana rage lalacewa na kayan aiki kuma yana ba da damar babban sauri, tsaftataccen sutura.

7. Yaushe layin Taro na Batir ya zama dole vs. masu walda masu tsaye?

Masu walda na tsaye cikakke ne don R&D, layin matukin jirgi, ko takamaiman matakan ƙananan taro. Layin Taro na Fakitin Baturi yana da mahimmanci don haɗawa, samar da babban girma na cikakkun kayayyaki ko fakiti. STYLER yana ƙirƙira layukan da ke sarrafa gabaɗayan jeri: stacking module, wurin ajiye busbar, walda (tabo ko Laser), gwajin lantarki, da haɗin kai na ƙarshe. Wannan yana haɓaka kayan aiki, rage girman kuskuren ɗan adam, yana tabbatar da ganowa, da haɓaka sararin bene.

8. Ta yaya ake magance spatter weld a cikin fakitin baturi, wanda zai iya haifar da gajeriyar kewayawa?

Spatter a cikin fakiti babban haɗari ne na aminci. A cikin waldawar tabo, ana sarrafa ta ta hanyar inganta sifar bugun bugun jini da ƙarfin lantarki. Spot Welders na tushen mu na Transistor yana ba da ingantaccen sarrafa bugun jini, yana rage haɓakar spatter sosai. A cikin waldawar Laser, ana rage spatter ta amfani da iskar gas mai karewa daidai, mafi kyawun matsayi, da ma'auni masu dacewa. An tsara tsarin STYLER don samar da tsaftataccen weld mai ƙarancin spatter mai mahimmanci don amincin fakitin.

9. Wadanne ma'auni ya kamata mu yi amfani da su don tabbatar da ingancin walda a cikin fakiti?

Bayan duban gani, ma'aunin tabbatarwa na maɓalli sun haɗa da:

Juriya na Wutar Lantarki / Ƙarfafawa: An auna a kowane haɗin haɗin walda; ƙananan juriya da daidaito yana da mahimmanci don aikin fakitin.

Ƙarfin Jawo/Bawo: Gwajin ɓarna na inji akan samfuran don tabbatar da amincin haɗin gwiwa ya dace da ƙayyadaddun bayanai.

Girman Nugget/Seam Shiga: An tabbatar ta hanyar bincike-binciken yanki yayin cancantar tsari.

Shigar da Bayanan Tsari: Kowane ma'aunin walda (a halin yanzu, lokaci, kuzari) ana yin rikodin su ta kayan aikin STYLER don cikakken gano abubuwan samarwa.

10. Ta yaya masana'antu ke daidaita walda don sababbin fakitin ƙira kamar CTC (Cell-to-Chassis) ko manyan fakitin tsarin?

Waɗannan ƙirar ƙira suna buƙatar hanyoyin walda waɗanda ke haifar da ƙarfi, abin dogaro na lantarki da wasu lokutan haɗin ginin akan sikeli mafi girma. Suna tura buƙatun don zurfin walda, gudu, da daidaito. Ana ƙara amfani da Welds na Laser High Power don dogon weld ɗin kabu akan fakitin fakiti da mashaya bas. STYLER yana kan gaba, yana haɓaka mafita tare da mahimmancin ƙarfi, daidaito, da ƙarfi don saduwa da waɗannan ƙalubalen taron taron na gaba.

Kammalawa

Walda fakitin baturi daidaitaccen horo ne da aka mayar da hankali kan ƙirƙirar ingantattun hanyoyin haɗin lantarki a cikin amintaccen taro mai aminci. Haɗin gwiwar da ya dace da zaɓin fasaha shine yanke shawara don nasarar samfurin ku.

A STYLER, muna ba da mafita da aka yi niyya don haɗa fakitin baturi. Daga ingantacciyar kwanciyar hankali na tushen Transistor na tushen Resistance Spot Welders da daidaitaccen daidaitaccen tsarin waldawar Laser ɗin mu zuwa ingantacciyar haɗaɗɗiyar aiki da kai na Layukan Majalisar Batir ɗin mu, mun himmatu wajen ƙarfafa masana'antar ku tare da dogaro, ƙira, da ƙwarewa.

Shirya don inganta aikin fakitin baturin ku? Tuntuɓi ƙungiyar ƙwararrun STYLER a yau don shawarwari.

Lokacin aikawa: Dec-11-2025